Taneco developed a solution for potato and vegetable processors to recycle wash water in a simple, compact and affordable way. The Taneco Agri WWT installation treats wash water and saves up to 95% of water.

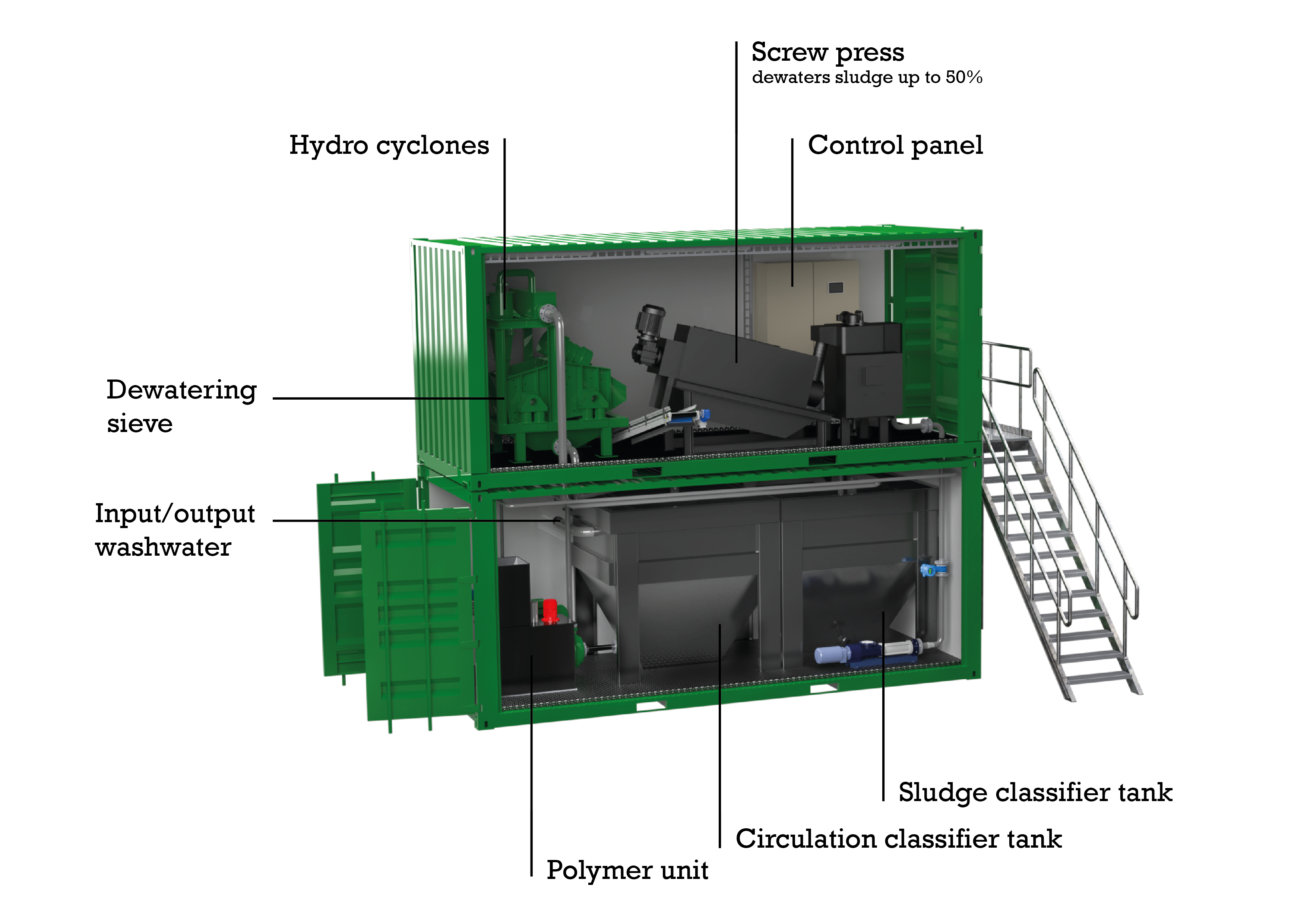

The system is suitable for treating wash water from washers with 10-100 m3/h. The complete system is built in two 20ft containers. The unit is fully tested in our workshop and is ready for operation after a short installation.

The Taneco Agri WWT contains the following components:

– Circulation classifier

– Sand recovery system

– Sludge classifier

– Sludge dewatering system

The process

The unit is equipped with connections for wash water inlet, outlet and clean water. The wash water will be pumped to the circulation classifier. In the classifier sand will settle. The settled sand will be pumped over the sand recovery system, where it will separate particles bigger than 25 micron. A dewatering sieve dewaters these solids up to 75% dry solids.

The desanded water will flow in to the sludge classifier tank and will be treated with a small amount of polymer to create settling of the sludge parts. A sludge dewatering system separates the sludge from the wash water. Cleaned water flows back to the washers, while sand and sludge are disposed by using a conveyor.